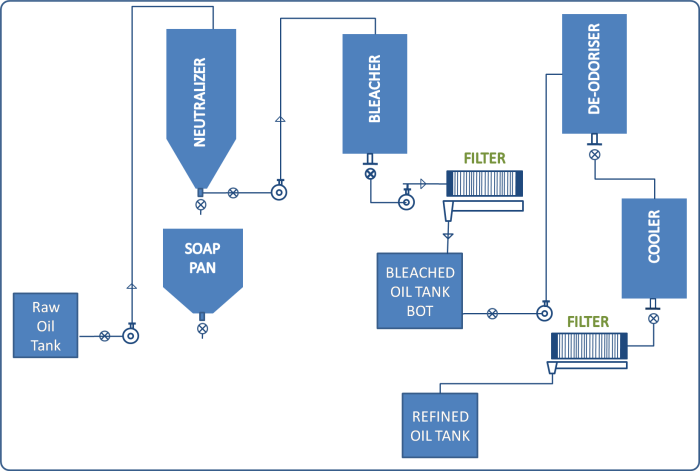

Oil refining is the procedure of processing pure vegetable oils into edible bakery fats and oils, and the procedure contains three basic processes at the very least.

The first process is neutralization, which involves neutralizing the oil to remove free fatty acids by adding caustic soda. The oil and caustic soda mixture is heated up and stirred to induce a chemical reaction between the two that causes soap stock to form edible oil refinery plant. The mixture is then left for the soap stock to settle at the bottom of the neutraliser from where it is taken out into a soap pan.

The second process is bleaching, where the neutralized oil is drawn from the neutraliser to a bleacher. The bleaching process is done under a vacuum and it removes the colour from the oil with chemicals like carbon black and bleaching earth. The oil is once again heated up to a higher temperature by thermic fluid coils and stirred to speed up the chemical reaction.

The last process is called deodorizing, which is the process of removing the smell from the oil under high vacuum. The bleached oil and chemicals are separated from each other in a Filter Press and clean, colourless oil is drawn into the Deodorizer. The clean oil is then heated through thermic fluid coils while live steam is injected into the oil through steam nozzles at the bottom of the deodorizer. The temperature of the oil is raised even higher and the odour of the oil is removed.

Palm oil refining includes an additional process named fractionation. This involves scientifically cooling the refined palm oil by chilling plant to separate palm olene and palm sterene. A crystallizing vessel with chilling pipe coils is used to cool the oil, which cause palm sterene crystals to form. Pure palm olene liquid is then filtered from the filter press and the palm sterene cake is retained click here to know more information.

Once these basic processes are complete, the oil goes to a cooler where water circulating coils reduce the heat until the oil is completely cooled. Again it goes to a second filter press where the completely refined, colourless and odourless oil is obtained and ready for packaging.