Groundnut seeds are a significant value seeds that may is usually publicized with the little bit making yet are particularly flexible and can be employed in a number of of items. Hence, Groundnut Oil Processing Plant can be probably the endeavours that can generate profits and always bring about the economical betterment of your oil mill plant.

Establish groundnut oil mill project includes feasibility analysis study preliminary research, purchase and installing of equipment in the ideal accommodation, crew recruiting of workers and more.

How to Setup Groundnut Oil Manufacturing Plant?

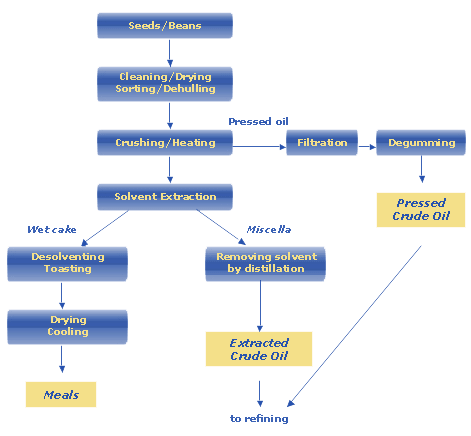

Firstly, the groundnut will need a complete sanitizing operation to take away crushed stone, track, vegetable dirt and any kind of impure substances. Then to get the sanitizing, the peanut seed be required to be organized for oil processing, which will requires over all size lowering of the groundnut kernel by separating them and then simply adjusting by simply altering their wetness content and temp, when staying the peanuts sizzling for some time of certain a few minutes.

Firstly, the groundnut will need a complete sanitizing operation to take away crushed stone, track, vegetable dirt and any kind of impure substances. Then to get the sanitizing, the peanut seed be required to be organized for oil processing, which will requires over all size lowering of the groundnut kernel by separating them and then simply adjusting by simply altering their wetness content and temp, when staying the peanuts sizzling for some time of certain a few minutes.

Secondary, the pre-processed groundnut are carried to Oil Press Machine, which will is the most used approach of groundnut oil manufacturing. The oil making machine screw warm constrained the peanut seed since it steps to move forward in which the distance is diminishing. As a result of stable frication and substantial tension, groundnut oil is obtained. Apart, since the temp in groundnut oil making machine pressing chamber goes up, groundnut oil extraction rate also boosts. At length, the the groundnut oil is exhausted from the oil drip pan of the screw oil press.

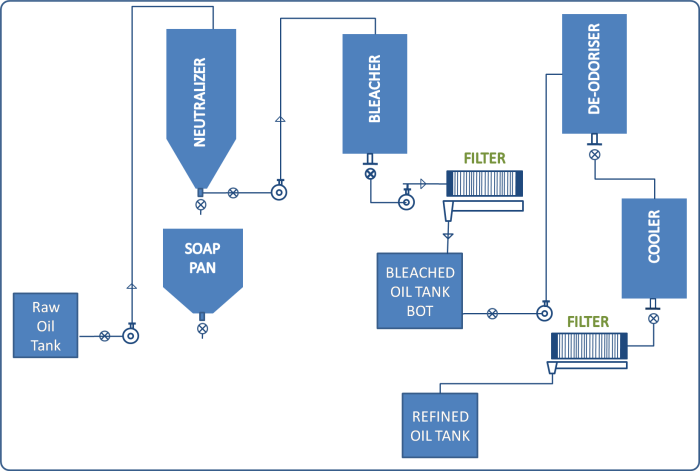

Additionally, the crude groundnut oil received via screw oil press is clarified and pure using various oil filter equipment. After filtering process, the groundnut oil quality is now available. But, some of groundnut oil mill plant will process the filter groundnut oil through professional edible oil refinery process to get higher quality final cooking oil.

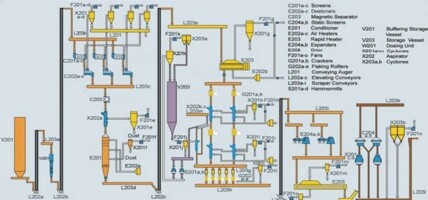

The first stage in the raw material handling line is the removal of all dust, lints, sticks, stems, leaves, sand, stones and other impurities. Tramp iron pieces are removed by magnetic separators. When foreign particles like stones having the same size as the seeds need to be removed, special destoning machines are incorporated in the cleaning line.

The first stage in the raw material handling line is the removal of all dust, lints, sticks, stems, leaves, sand, stones and other impurities. Tramp iron pieces are removed by magnetic separators. When foreign particles like stones having the same size as the seeds need to be removed, special destoning machines are incorporated in the cleaning line. Oil frame filter press always be used as a oil purifier in the oil plants for edible oil or biodiesel. This model filter is suitable for filter crude oil and refined oil, and it is also can be used to filter bleaching oil in the refining workshop.

Oil frame filter press always be used as a oil purifier in the oil plants for edible oil or biodiesel. This model filter is suitable for filter crude oil and refined oil, and it is also can be used to filter bleaching oil in the refining workshop.

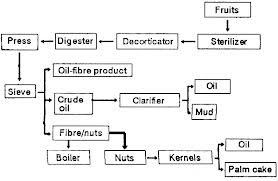

To establish oil palm plantation, it involves getting a good site where rich, well drained acidic soils are abundant. The soil should have adequate quantities of potassium, magnesium and nitrogen. Soil tests should therefore be carried out to determine the nutrient status of the land.It is usually better to use the early maturing variety called tenera, which bears fruits as from the fourth year.

To establish oil palm plantation, it involves getting a good site where rich, well drained acidic soils are abundant. The soil should have adequate quantities of potassium, magnesium and nitrogen. Soil tests should therefore be carried out to determine the nutrient status of the land.It is usually better to use the early maturing variety called tenera, which bears fruits as from the fourth year.

Neem oil has a weighty advantage to farmers, other people in other fields too can require it but in comparatively minor situations. It is a valuable insecticide and pesticide, fungal diseases on crops and chewing insects find themselves outside the garden boundaries when a farmer applies it. It as well protects people and animals from biting bugs. In some nations, especially in the western world, the most popular use of neem oil is the spraying on crops and animals for protection against pests, insects and fungal diseases.

Neem oil has a weighty advantage to farmers, other people in other fields too can require it but in comparatively minor situations. It is a valuable insecticide and pesticide, fungal diseases on crops and chewing insects find themselves outside the garden boundaries when a farmer applies it. It as well protects people and animals from biting bugs. In some nations, especially in the western world, the most popular use of neem oil is the spraying on crops and animals for protection against pests, insects and fungal diseases. In the large-scale production of neem oil, the first step is the mechanical pressing for the extraction of initial oil. Later, the pre-pressed neem cake is sent to the solvent extraction chamber for further oil extraction. The choice of the oil mill depends on the budget and the business objective. Choosing the appropriate brand name is important so that you can also find the spare parts easily.

In the large-scale production of neem oil, the first step is the mechanical pressing for the extraction of initial oil. Later, the pre-pressed neem cake is sent to the solvent extraction chamber for further oil extraction. The choice of the oil mill depends on the budget and the business objective. Choosing the appropriate brand name is important so that you can also find the spare parts easily. The dry coconut oil processing entails removing the fleshy part from the fruit and letting it to dry. The drying options can either be using direct sunlight, heat from the fire or in the furnaces. The dried coconut material is known as copra. (See more of

The dry coconut oil processing entails removing the fleshy part from the fruit and letting it to dry. The drying options can either be using direct sunlight, heat from the fire or in the furnaces. The dried coconut material is known as copra. (See more of