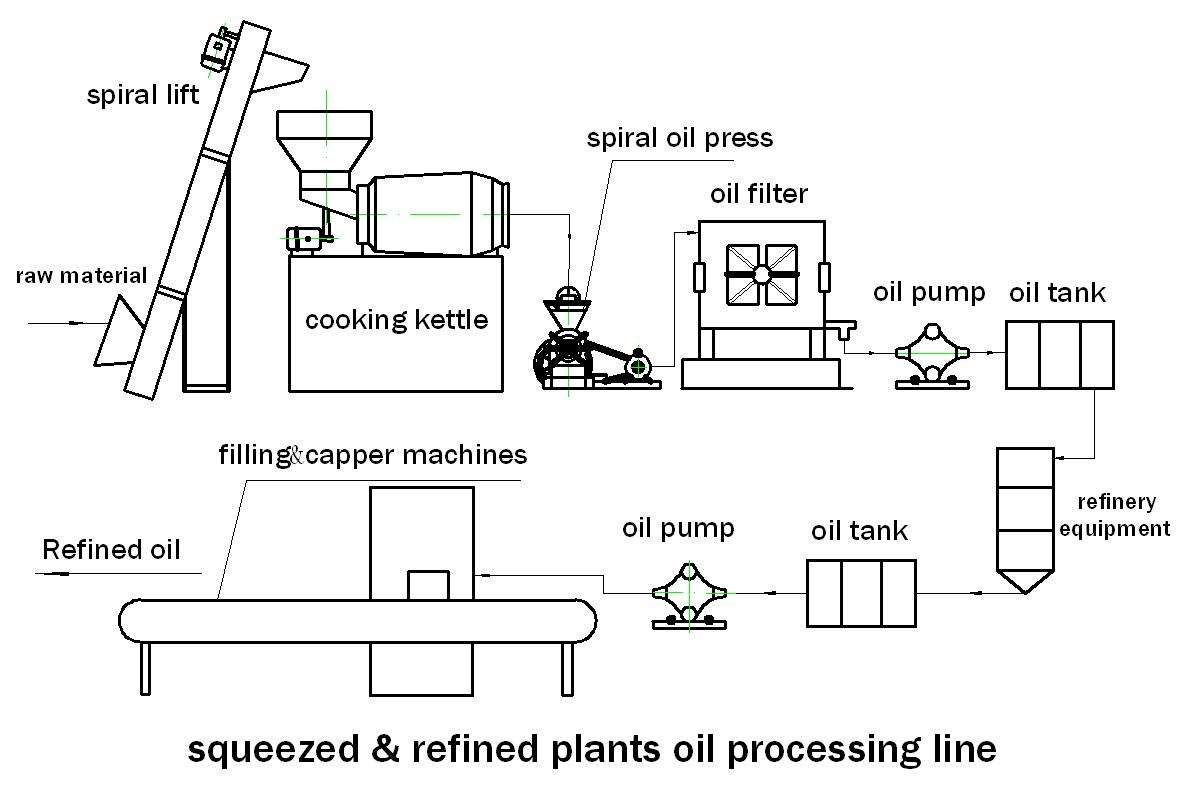

Oil press machine was designed to allow an average person to produces their own oil from the available seeds. The oil can be pressed to 170 degrees Fahrenheit. There are various oils that can be extracted using this press. These can be from sunflower, rapeseed, linseed and any other oil bearing seeds. The pressed oil can be stored in IBCs which are usually simple and flexible storage means. However, large tanks are also preferred.

The oil produced from oil press extraction can be used as fuel in engines, as edible cooking oil, in production of biodiesel and production of environmental friendly lubricating oils. The screw oil press machine is easy to use. The seed is first placed under an increasing pressure as it passes through a chamber that is tapered. Due to the high compression level that is as a result of pressure produced by the high temperature, oil is cast out through a set of rigid circular band of metal. The approximate amount of ton of oil that is made from the whole process ranges from 250 to 300 liters. However, this depends on the original content of the oil, moisture content and how clean the sample was.

The end results from the oil extraction process are affected by various factors. One is the ambient temperature. The rates of oil extraction are dependant on the temperature produced in the press. Power also plays a major role in the machine.

These are considered to be the 5 main parts of this oil press. In simple terms, it is clear to say that this oil press is a crude oil processing machine.

These are considered to be the 5 main parts of this oil press. In simple terms, it is clear to say that this oil press is a crude oil processing machine.

Expeller-pressed oil is primarily obtained mechanically. Popular application of this type of

Expeller-pressed oil is primarily obtained mechanically. Popular application of this type of  The left-over, which is usually rich in nutrients are given to the nearby community or fed to animals. Oil obtained from such a process is normally undertaken by reputable firms. They do ensure that the products they avail to the nearby community are fit for human consumption.

The left-over, which is usually rich in nutrients are given to the nearby community or fed to animals. Oil obtained from such a process is normally undertaken by reputable firms. They do ensure that the products they avail to the nearby community are fit for human consumption.