Oil palm is native to West Africa. Nigeria used to be the world’s largest producer of oil palm before the crude oil boom era. Malaysia has now taken the leading position. Oil palm plantation and allied industries is now the main stay of Malaysian economy. Malaysia came to Nigeria in the 70s to obtain oil palm seeds and seedlings. Oil palm can be used in various ways; the leaves are used in making brooms and as roofing materials (in the rural areas). The bark of the fond can be peeled and woven into baskets.

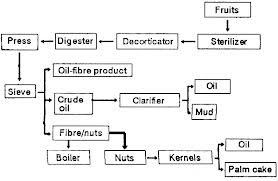

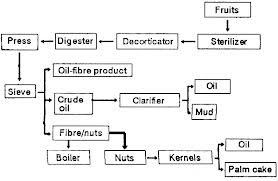

The main trunk can be split like sawn timbers and used as part of building materials. Palm wine can be obtained from oil palm, red palm oil is readily obtainable from the fresh fruit bunches. When the fruit is processed the residue obtained can be used as fuel (for cooking and fertilizer to improve soil nutrient). Red palm oil is used in cooking, making soap, candle and margarine. Palm kernel oil can be extracted from the nut.

The residue obtainable in the process of palm kernel oil extraction otherwise called palm kernel cake is used as livestock feed. Palm kernel oil is used in vegetable oil and soap making. Palm Kernel shells are also useful as energy source and industrial raw materials such as mosquito coils.

The uses to which oil palm can be made seem non exhaustive. This clearly indicates that investment made in the establishment of oil palm plantation is nothing but a wise one. The market is guaranteed for all the products of oil palm plantation in this era of global food crisis.

Technical information

To establish oil palm plantation, it involves getting a good site where rich, well drained acidic soils are abundant. The soil should have adequate quantities of potassium, magnesium and nitrogen. Soil tests should therefore be carried out to determine the nutrient status of the land.It is usually better to use the early maturing variety called tenera, which bears fruits as from the fourth year.

To establish oil palm plantation, it involves getting a good site where rich, well drained acidic soils are abundant. The soil should have adequate quantities of potassium, magnesium and nitrogen. Soil tests should therefore be carried out to determine the nutrient status of the land.It is usually better to use the early maturing variety called tenera, which bears fruits as from the fourth year.

Other requirements include seedlings procurement; this can be obtained from reputable nurseries. Prospective investors must engage the services of Agricultural experts in the course of establishing this project. Other cultural practices are planting, regular weeding, pruning and fertilizer application. Serious minded investors will be guided accordingly in the implementation of this project.

Income analysis

A matured plantation will start to give investor five 5 tons per hectare of red palm oil annually from the fourth year per hectare. 100 metric tons of oil can be obtained annually from 20 hectare plantation. A ton of red palm oil is a minimum of N150,000. Gross revenue of N15 million is obtained from red palm oil.

We can also get three metric tons of palm kernel per hectare. This gives us 60 tons from 20 hectares. This translates to annual income of N4.2 million. Total income realisable is about N19.2 million while the annual operating expense is put at N5.8 million.

This leaves us with net income N13.4 million annually for the investor for the rest of his/her live. There are still other sources of income such as palm fronds and palm kernel shells. Serious minded investors can be assisted in the realisation of this worth while investment.

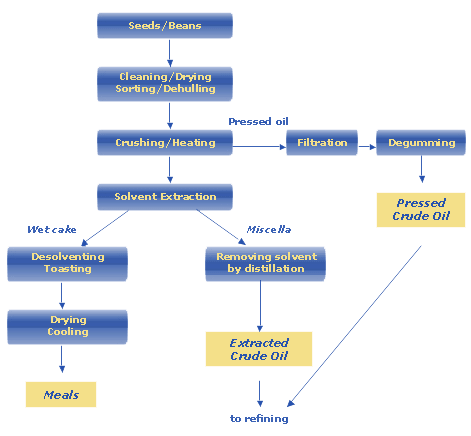

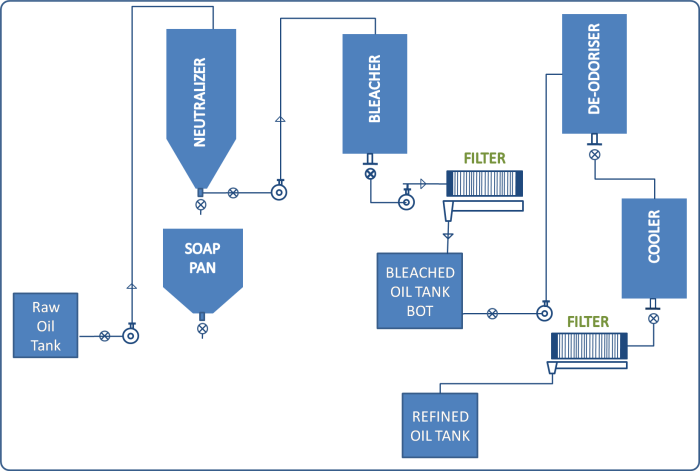

Oil frame filter press always be used as a oil purifier in the oil plants for edible oil or biodiesel. This model filter is suitable for filter crude oil and refined oil, and it is also can be used to filter bleaching oil in the refining workshop.

Oil frame filter press always be used as a oil purifier in the oil plants for edible oil or biodiesel. This model filter is suitable for filter crude oil and refined oil, and it is also can be used to filter bleaching oil in the refining workshop.

To establish oil palm plantation, it involves getting a good site where rich, well drained acidic soils are abundant. The soil should have adequate quantities of potassium, magnesium and nitrogen. Soil tests should therefore be carried out to determine the nutrient status of the land.It is usually better to use the early maturing variety called tenera, which bears fruits as from the fourth year.

To establish oil palm plantation, it involves getting a good site where rich, well drained acidic soils are abundant. The soil should have adequate quantities of potassium, magnesium and nitrogen. Soil tests should therefore be carried out to determine the nutrient status of the land.It is usually better to use the early maturing variety called tenera, which bears fruits as from the fourth year.