If you are involved in oil pressing, it is important for you to know how well an oil press works. In most cases, the manufacturers provide their customers with directions on how the machine is supposed to be used. This in turn will help your machine to work in a designated way. Remember, if you have ample knowledge about the machine, there is no doubting that you will achieve the best results when it comes to oil pressing.

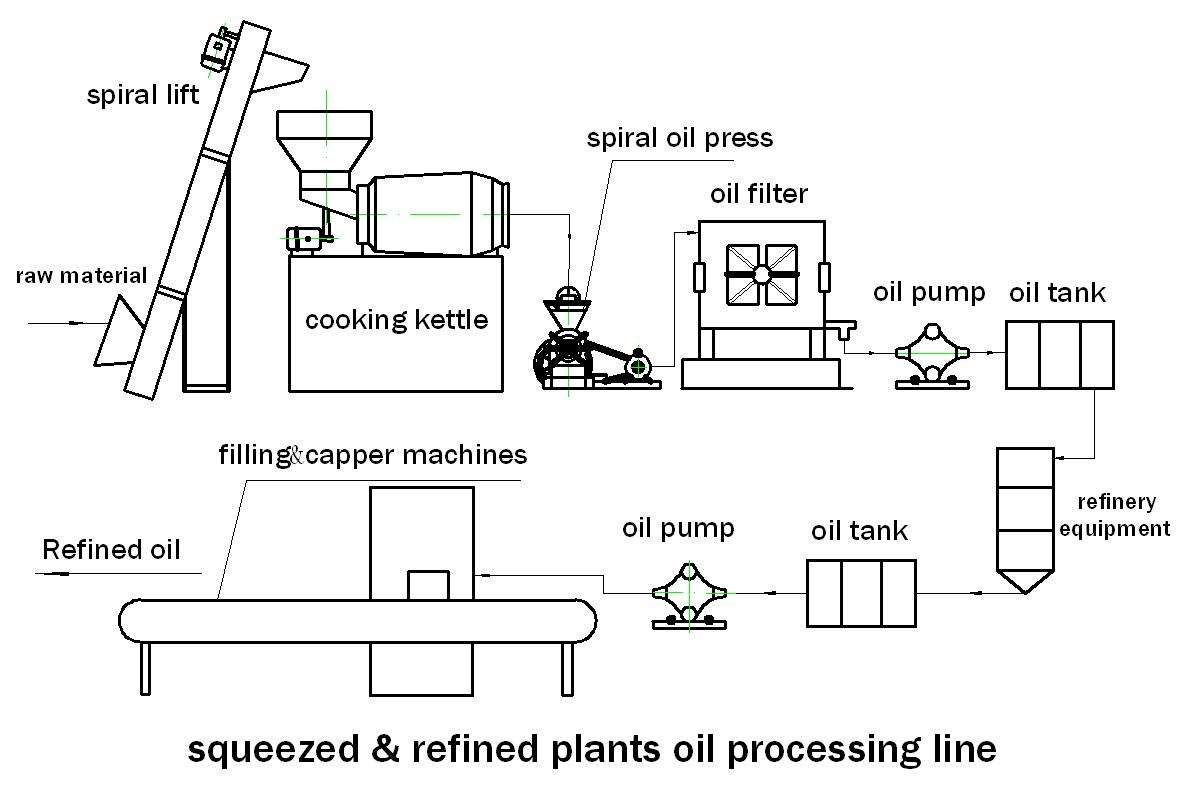

Oil press works with different types of materials and as such, it is important for you to identify with the type of material that you will use on your oil. Press before making a purchase. The raw materials are put inside the oil press and a tray placed beneath it in order to collect any oil being produced. The raw materials can either be sunflower seeds, sesame seeds and olive seeds among others. Ensure that you have put the right amount of the dried seeds into the process for the oil pressing process to commence.

Once the oil pressing begins, the oil produced will be collected into the tray. The oil press comes with a pedestal which plays a major role in emptying the oil into a cup. At this point, you have an obligation of filtering the oils collected in order to remove any foreign matter and other particles that can easily burn the oil.

Expeller-pressed oil is primarily obtained mechanically. Popular application of this type of

Expeller-pressed oil is primarily obtained mechanically. Popular application of this type of  The left-over, which is usually rich in nutrients are given to the nearby community or fed to animals. Oil obtained from such a process is normally undertaken by reputable firms. They do ensure that the products they avail to the nearby community are fit for human consumption.

The left-over, which is usually rich in nutrients are given to the nearby community or fed to animals. Oil obtained from such a process is normally undertaken by reputable firms. They do ensure that the products they avail to the nearby community are fit for human consumption. Mention of vegetable oil may sound easy but the processing of it is not as easy. It entails growing of your feed stock plants, waiting for months on end while tending them, harvesting and eventually running it through a

Mention of vegetable oil may sound easy but the processing of it is not as easy. It entails growing of your feed stock plants, waiting for months on end while tending them, harvesting and eventually running it through a